Hi Tech Lean: Top 3 Powerful Benefits in 2025

Revolutionizing Manufacturing: The Hi Tech Lean Approach

Hi tech lean is a modern manufacturing methodology that combines traditional lean principles with advanced digital technologies to dramatically improve productivity, quality, and operational efficiency.

What is Hi Tech Lean?

- Definition: The integration of lean manufacturing principles with Industry 4.0 technologies including IoT, AI, and automation

- Core Focus: Eliminating waste while leveraging real-time data for continuous improvement

- Key Difference: Unlike traditional lean, hi tech lean uses digital tools to identify and solve problems faster

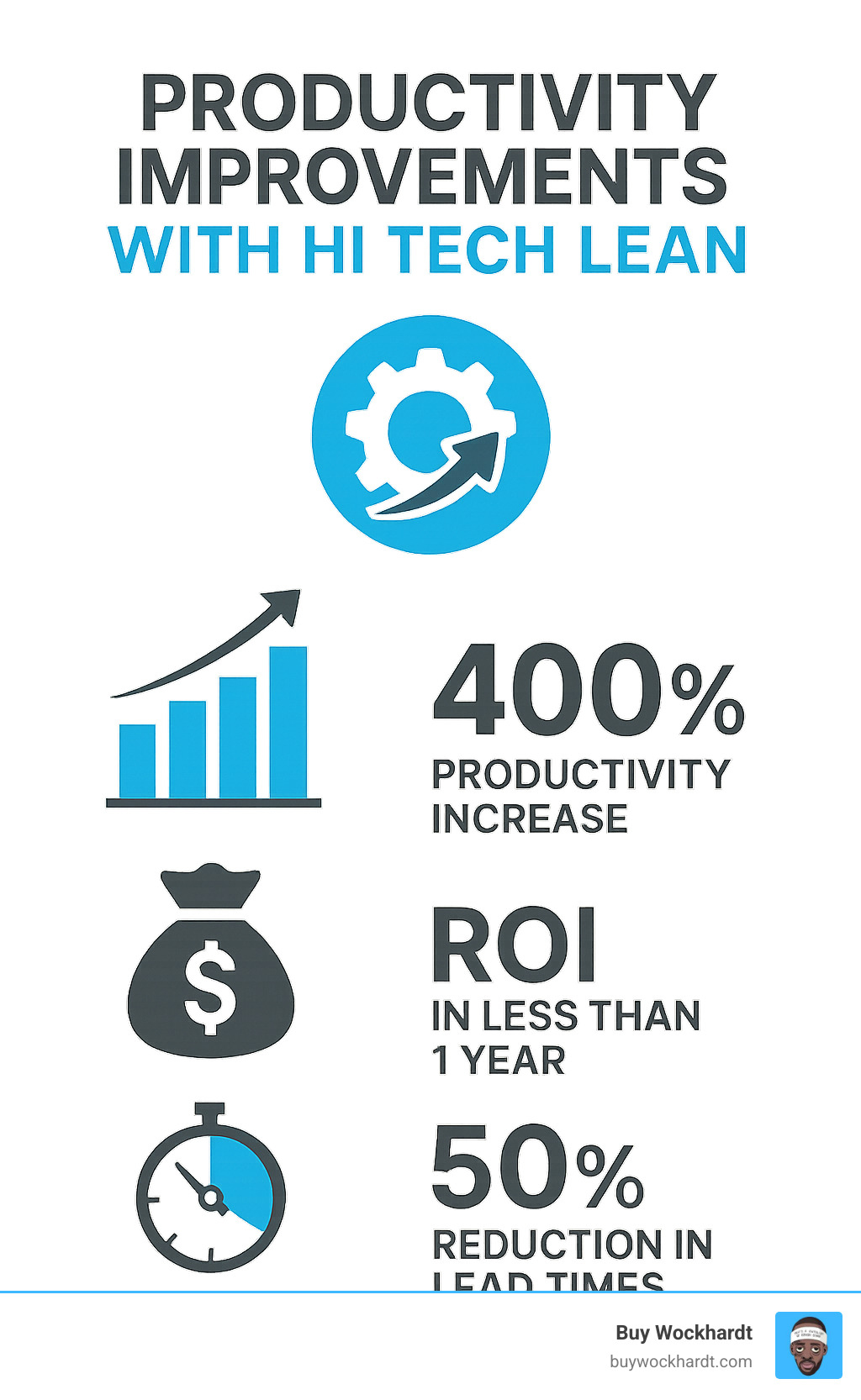

- Typical Results: 400% productivity improvements with ROI in less than 1 year

Hi tech lean represents the evolution of traditional lean manufacturing principles for the digital age. While Toyota’s lean system focused on manual processes and visual management, hi tech lean harnesses the power of data, automation, and connected systems to achieve unprecedented levels of efficiency.

Companies implementing hi tech lean methodologies are seeing remarkable results. According to research, KSolutions’ customers have reported a 400% improvement in productivity after implementing hi-tech lean manufacturing solutions, with most major process improvement projects delivering ROI in less than one year.

The beauty of hi tech lean is that it’s not just for large corporations. Small and medium-sized enterprises can leverage these principles through cloud-based tools and modular automation to remain competitive in increasingly challenging markets.

At its core, hi tech lean maintains the fundamental lean principle of eliminating waste, but boosts this process with digital tools that provide real-time insights, predictive capabilities, and autonomous optimization. Instead of waiting for weekly quality reports, managers can access live dashboards showing production metrics. Rather than reactive maintenance, smart sensors predict equipment failures before they happen.

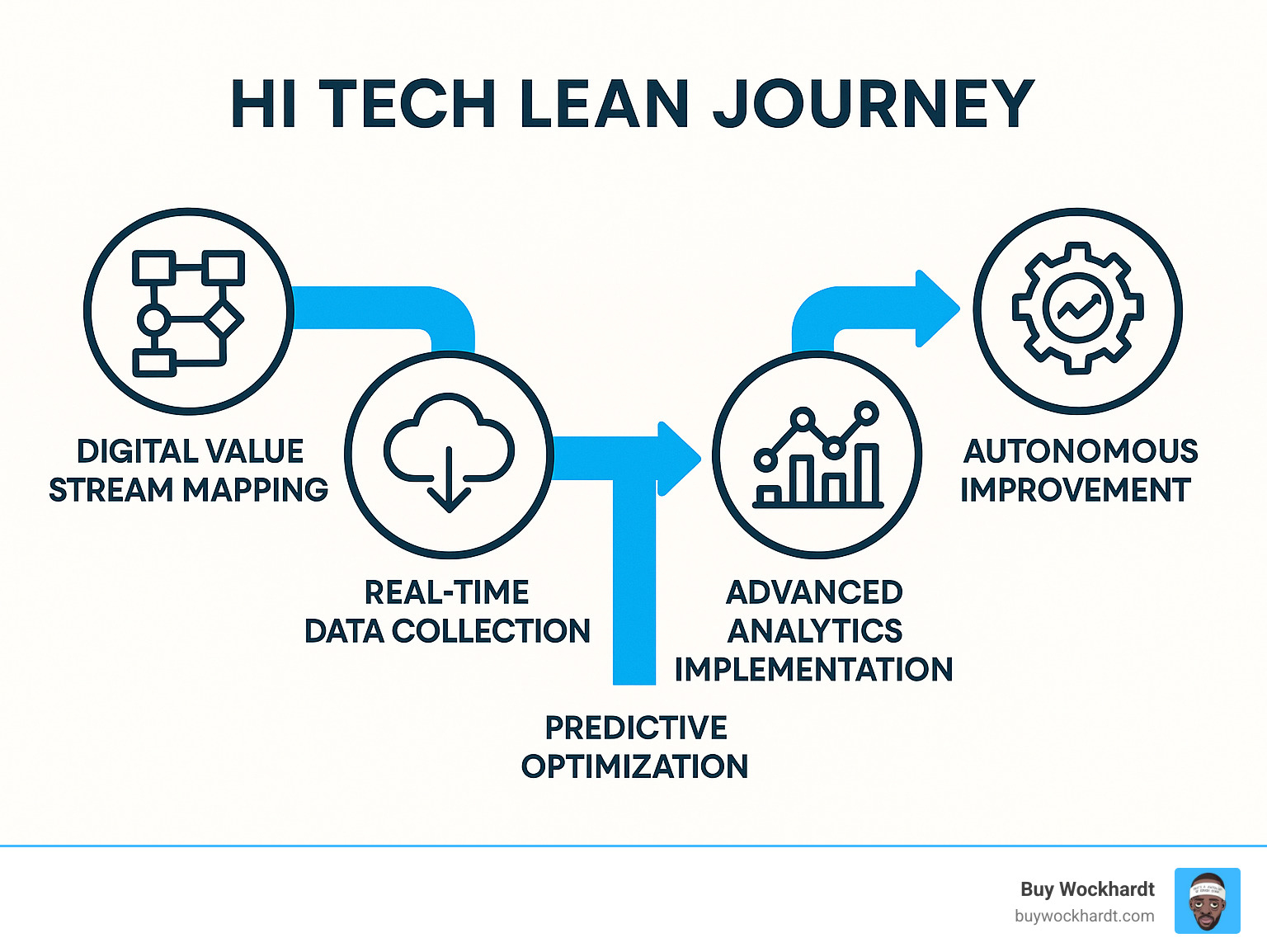

For organizations beginning their hi tech lean journey, the approach typically involves digitizing key processes, implementing connected monitoring systems, and building a culture that accepts both continuous improvement and technological innovation.

Hi Tech Lean 101: What Sets It Apart

Ever wondered what makes hi tech lean truly special in today’s manufacturing world? It’s like taking the classic lean principles we’ve known for decades and giving them a digital boost. While traditional lean focused on manual processes and physical visual management, hi tech lean brings data, smart technology, and automation into the mix to create something remarkably more powerful.

Think of it as the difference between a paper map and GPS navigation. Both get you to your destination, but one offers real-time updates, predictive suggestions, and a much smoother journey.

| Aspect | Traditional Lean | Hi Tech Lean |

|---|---|---|

| Data Collection | Manual recording | Automated, real-time sensors |

| Analysis | Periodic, retrospective | Continuous, predictive |

| Problem Solving | Human-driven | AI-assisted |

| Visualization | Physical boards | Digital dashboards |

| Process Control | Standard work documents | Digital work instructions with feedback |

| Improvement Cycle | Weekly/monthly kaizen | Continuous optimization |

| Inventory Management | Physical kanban | E-kanban with predictive ordering |

| Quality Control | Sampling inspection | 100% automated inspection |

| Maintenance | Preventive scheduling | Predictive/condition-based |

| Decision Making | Experience-based | Data-driven |

Origins & Evolution of hi tech lean

The story of hi tech lean begins with Toyota’s Production System (TPS) that changed manufacturing forever. Those foundational principles of waste elimination and flow remain at the heart of everything, but the digital revolution has taken these concepts to entirely new heights.

What started as simple digital spreadsheets and basic manufacturing software has blossomed into something truly remarkable. Today’s hi tech lean environments feature interconnected IoT sensors, smart machines that communicate with each other, and AI systems that can predict problems before they happen.

The arrival of Industry 4.0 provided the perfect technological playground for hi tech lean to flourish. This marriage of physical production with digital technologies has created manufacturing environments where everything – machines, products, and people – speaks the same digital language, allowing for levels of optimization that were once impossible to achieve.

Core Definitions & Key Differences

What truly makes hi tech lean stand out from its traditional predecessor? It’s all about how it transforms fundamental lean concepts:

Value-stream digitalization turns static process maps into living, breathing digital models that update in real-time as conditions change on your factory floor. Instead of outdated snapshots, you get a continuous live feed of how value flows through your operation.

Real-time data loops eliminate the waiting game. Rather than collecting data at the end of a shift or week, hi tech lean environments capture, analyze, and act on information as it happens, creating a continuous improvement cycle that never sleeps.

Predictive decision-making might be the most exciting advancement. Instead of reacting to problems after they occur, hi tech lean systems can forecast issues before they happen and suggest the optimal solution, often before humans even notice a trend developing.

Digital twins create virtual replicas of your actual processes, allowing you to test changes and improvements in a risk-free environment before implementing them on your actual production line.

Autonomous improvement takes kaizen to the next level, with systems that can self-optimize based on parameters and learning algorithms, complementing human creativity with computational power.

The fundamental shift is clear – while traditional lean relied heavily on human observation and intervention, hi tech lean improves these human capabilities with digital technologies, creating a partnership that achieves greater precision, speed, and scalability in improvement efforts than either could achieve alone.

Core Principles & Digital Integration Tools

The magic of hi tech lean happens when traditional lean wisdom meets cutting-edge digital tools. This powerful combination creates a manufacturing approach that’s more responsive, efficient, and intelligent than anything we’ve seen before.

Traditional Lean Principles in a Digital Context

Remember good old kaizen? In the hi tech lean world, continuous improvement never sleeps. Instead of waiting for monthly improvement meetings, digital kaizen happens in real-time. Smart systems constantly analyze production data, spotting opportunities human eyes might miss. Imagine walking into your facility and seeing your analytics dashboard has already identified three process tweaks that could save you thousands this week.

The humble kanban card has evolved into sophisticated e-kanban systems that do much more than signal when to order more parts. Modern e-kanban dashboards automatically track inventory levels and can even place orders with suppliers when stocks run low. No more emergency rush orders or production delays due to missing components!

Just-In-Time production gets a serious upgrade with predictive analytics. Rather than simply responding to current orders, hi tech lean systems can forecast demand patterns and adjust production schedules automatically. This means you’re always producing exactly what’s needed, when it’s needed – the true essence of JIT, but with digital superpowers.

Error-proofing (poka-yoke) reaches new heights when improved with vision systems and sensors. A camera system that can inspect every single product with perfect consistency never gets tired, never needs a coffee break, and catches subtle defects a human might overlook after hours on the line.

Digital Integration Tools

Today’s hi tech lean environment runs on a network of smart, connected tools working together. IoT sensors serve as the nervous system, constantly gathering data from every corner of your operation. These tiny devices monitor everything from machine vibrations (warning of potential failures) to temperature fluctuations that might affect product quality.

Manufacturing Execution Systems (MES) act as the central brain, connecting planning to execution to analysis. The beauty of modern MES platforms is their scalability – you don’t need to implement everything at once. Start with the modules that address your biggest pain points, then expand as you see results.

Digital twins might sound like science fiction, but they’re becoming essential to forward-thinking manufacturers. These virtual replicas of your physical processes let you test improvement ideas in a risk-free environment. Want to see how a new production sequence might affect throughput? Run it on your digital twin first, without disrupting actual production.

Cloud analytics have democratized advanced data analysis. Even smaller companies can now access powerful computing resources without massive infrastructure investments. This means the sophisticated optimization tools once available only to industry giants are now within reach for operations of all sizes.

The healthcare industry has acceptd these principles with impressive results. Scientific research on lean healthcare change shows how digital lean tools have transformed patient care by reducing wait times and optimizing resource use – proving these concepts work beyond traditional manufacturing.

Automation & Industry 4.0 Synergy

The real power of hi tech lean emerges when it joins forces with Industry 4.0 technologies. Collaborative robots (cobots) work alongside human team members, handling the repetitive, physically demanding tasks while humans focus on work requiring judgment and creativity. This partnership creates a more engaging workplace while boosting productivity.

AI vision systems bring superhuman inspection capabilities to your quality process. These systems can spot microscopic defects at speeds impossible for human inspectors, ensuring only perfect products reach your customers.

Edge computing keeps critical processing close to where the action happens. When milliseconds matter – like in high-speed quality checks – edge computing eliminates the delays of sending data to distant servers and waiting for responses.

Self-optimizing production cells represent perhaps the most advanced expression of hi tech lean principles. These flexible units can reconfigure themselves based on changing product requirements, making small-batch and customized production economically viable. Imagine changing your entire production setup with a few clicks rather than days of physical reconfiguration.

KPI Dashboards & Software Stack

Modern hi tech lean environments make performance visible to everyone. Real-time dashboards display crucial metrics like Overall Equipment Effectiveness (OEE), First Pass Yield (FPY), and takt time, creating immediate awareness of how things are running. When everyone can see the current state, problems get addressed faster.

Statistical Process Control has evolved from periodic sampling to continuous monitoring. Automated SPC tools watch process parameters constantly, alerting operators to drift before defects occur – preventing problems rather than just detecting them.

Predictive maintenance has perhaps the clearest ROI in the hi tech lean toolkit. Machine learning algorithms analyze equipment data patterns to predict failures before they happen. Instead of emergency breakdowns that halt production, maintenance gets scheduled during planned downtime, dramatically reducing disruption.

Energy consumption monitoring adds a sustainability dimension to hi tech lean. Real-time tracking of energy usage identifies waste and supports green initiatives – good for both the planet and your bottom line.

All these capabilities rest on a thoughtfully designed software foundation that includes data collection systems, storage solutions, analytics platforms, visualization tools, and integration layers. This connected ecosystem ensures that your hi tech lean journey delivers measurable, sustainable improvements that flow straight to your bottom line.

Implementation, Case Studies & Performance Metrics

Implementing hi tech lean is like renovating your home – you need a solid plan, the right tools, and a clear vision of what success looks like. Organizations across industries have transformed their operations using this approach, achieving impressive results that speak for themselves.

Step-by-Step Deployment Framework

The journey to hi tech lean excellence typically unfolds in six manageable stages, rather than an overwhelming all-at-once change.

It begins with a thorough diagnostic assessment – think of it as a complete health check for your operations. This establishes your starting point and highlights the most promising areas for improvement.

Next comes crafting a strategic roadmap that balances quick wins with longer-term goals. This is where you chart your course, making sure technology investments align with business priorities.

The pilot cell implementation phase is particularly exciting – it’s your chance to experiment in a controlled environment. One manufacturing client described this as their “playground for innovation” where teams could test new ideas without risking broader operations.

Building the right technology infrastructure follows, creating the digital nervous system that will power your change. Cloud-based solutions often make the most sense here, especially for companies wanting flexibility without massive upfront investments.

As successes emerge, the scale-up and standardization phase kicks in. This is where the magic happens – taking what works in one area and thoughtfully expanding it across the organization.

Finally, establishing a continuous learning system ensures your change doesn’t stall out. Regular reviews, cross-functional teams, and knowledge-sharing become part of your company’s DNA.

Case Studies & Success Stories

Real-world examples bring the power of hi tech lean to life across diverse sectors.

In high-tech manufacturing, a semiconductor producer achieved an astonishing 400% productivity improvement by integrating IoT sensors with advanced analytics. KSolutions reported that their client not only boosted output but dramatically reduced quality issues that had previously plagued production.

A medical technology manufacturer faced stringent regulatory challenges while trying to improve efficiency. Their hi tech lean approach incorporated computer vision inspection and electronic batch records, creating a seamless compliance process while boosting productivity. Their approach aligns perfectly with modern FDA expectations, as outlined in scientific discussions on FDA compliance for tech processes.

Healthcare Dynamic transformed hospital operations with digital patient flow management and predictive staffing models. The results were remarkable – shorter wait times, better resource use, and happier patients. One nurse manager noted, “We finally feel like we’re spending our time caring for patients instead of hunting down equipment.”

Perhaps most inspiring is the story of a small manufacturing enterprise that proved hi tech lean isn’t just for corporate giants. By leveraging affordable cloud-based tools and IoT sensors, this precision parts maker achieved results comparable to much larger competitors, with ROI in under 12 months. Their CEO remarked, “We thought this kind of technology was out of reach for a company our size – we couldn’t have been more wrong.”

Measuring Success

What gets measured gets improved – and hi tech lean implementations thrive on clear, consistent metrics.

Operational metrics provide the day-to-day pulse of your change. Lead time shows how quickly you can deliver on customer promises, while cycle time reveals the efficiency of individual processes. OEE (Overall Equipment Effectiveness) offers a comprehensive view of how well your equipment is performing, combining availability, performance, and quality into a single powerful metric.

Financial metrics translate operational improvements into bottom-line impact. ROI validates your technology investments, while cost per unit reveals true efficiency gains. Companies implementing hi tech lean typically see dramatic improvements in inventory turns, freeing up capital while improving service levels.

Customer satisfaction becomes more measurable through metrics like on-time delivery and Net Promoter Score. One medical device manufacturer saw their NPS jump from 32 to 78 within six months of their hi tech lean implementation, as quality and reliability improvements directly impacted customer experience.

Innovation metrics track how well your organization adapts and evolves. Time to market often shows dramatic improvement, as digital workflows eliminate bottlenecks in product development. The improvement idea implementation rate reveals how effectively your organization captures and acts on employee insights.

Perhaps most importantly, people metrics ensure your change engages rather than alienates your workforce. Employee engagement typically rises as frustrating manual tasks are automated and workers gain new digital skills. Safety incidents almost always decrease as predictive systems identify risks before they cause harm.

The most successful implementations establish clear baseline measurements before making changes and then track progress using automated data collection. This creates an objective, fact-based foundation for continuous improvement.

Benefits, Challenges & Future Trends

The journey to hi tech lean is both exciting and challenging. While the rewards can be transformative, organizations need to steer potential problems with care and strategic planning.

Key Benefits

When companies accept hi tech lean, they often experience remarkable improvements across their operations. KSolutions’ customers consistently report productivity boosts of 200-400% – not just incremental gains, but truly transformative results. These aren’t just numbers on a spreadsheet; they represent real competitive advantages in today’s challenging markets.

Beyond pure productivity, hi tech lean creates organizations that can pivot quickly when market conditions change. Imagine being able to reconfigure your production schedule in real-time when a major customer places an unexpected order. That kind of agility is priceless in our fast-changing world.

The financial benefits extend far beyond labor savings. Companies implementing hi tech lean typically see dramatic reductions in inventory costs (why tie up capital in excess stock when your systems can predict exactly what you’ll need?), lower energy bills, fewer quality-related expenses, and more efficient maintenance programs that prevent costly breakdowns.

Quality improvements are particularly noteworthy. With automated inspection systems and built-in error-proofing, products become more consistent and reliable. Your customers notice this difference – and reward it with loyalty and referrals.

Perhaps most valuable in today’s data-driven world is the improved decision-making capability that comes with hi tech lean. Rather than relying on gut feelings or outdated reports, leaders can access real-time insights that illuminate trends, predict problems before they occur, and guide resource allocation for maximum impact.

And let’s not forget sustainability – an increasingly important consideration for businesses of all sizes. Hi tech lean systems naturally optimize resource usage, reducing waste and environmental impact while often cutting costs simultaneously. It’s a rare win-win for both business and planet.

Challenges & Adoption Barriers

Despite these compelling benefits, the path to hi tech lean isn’t always smooth. Many organizations struggle with outdated IT systems that weren’t designed for today’s connected world. Integrating modern IoT sensors and analytics platforms with legacy systems can feel like trying to connect your smartphone to an 8-track player.

The skills challenge is equally daunting. Hi tech lean requires people who understand both manufacturing processes and digital technologies – a relatively rare combination. Finding or developing talent with this hybrid skill set remains difficult for many organizations, especially smaller ones with limited training resources.

Financial problems can also slow adoption. While the return on investment is typically strong (often less than a year), the initial costs for technology, infrastructure, and training can be substantial. Building a compelling business case requires looking beyond simple payback periods to consider strategic advantages that may be harder to quantify.

Perhaps the most significant barrier is human nature itself. Change is hard, and hi tech lean requires shifts in mindset, behaviors, and organizational structures that can trigger resistance. People who’ve mastered traditional processes may feel threatened by new technologies or worry about job security.

Finally, there’s the challenge of data quality. Hi tech lean depends on reliable, accurate information flowing throughout your systems. Without proper data collection, validation, and governance processes, even the most sophisticated technologies will struggle to deliver meaningful insights.

Overcoming Adoption Barriers

Successful organizations tackle these challenges with thoughtful strategies rather than brute force. They start small, focusing on high-impact pilot projects that demonstrate value quickly and build momentum for broader change. These early wins create enthusiastic internal champions who help drive wider adoption.

Many companies find that cloud-based solutions offer a path around legacy IT constraints. These platforms provide sophisticated capabilities without requiring massive infrastructure investments or long implementation timelines. They also scale easily as your needs grow.

Forward-thinking leaders invest heavily in skills development, creating comprehensive training programs that blend lean principles with digital literacy. The best programs address both technical skills and the emotional aspects of change, helping people understand not just how to use new tools but why they matter.

Business cases for hi tech lean should look beyond simple cost reduction to include strategic benefits that may be harder to quantify but ultimately more valuable – like improved customer satisfaction, increased organizational agility, and improved innovation capability.

Throughout the journey, visible leadership commitment makes all the difference. When executives actively champion hi tech lean initiatives, participate in training, and celebrate successes, they send a powerful message about organizational priorities that helps overcome resistance.

SMEs & Competitive Edge

Small and medium-sized enterprises face unique challenges in adopting hi tech lean, but they also have distinct advantages. Their smaller size often means greater agility and less bureaucracy to steer when implementing changes.

Cloud-based software-as-a-service solutions have been a game-changer for smaller organizations. These platforms provide enterprise-grade capabilities without requiring massive upfront investments or specialized IT staff. With subscription-based pricing that scales with business growth, even modest operations can access sophisticated tools once available only to industry giants.

For physical automation, a modular approach works best. Start with high-impact areas where the return will be most immediate, then expand as resources allow. Collaborative robots (cobots) are particularly well-suited to SMEs, offering flexibility and lower implementation costs than traditional automation systems.

Don’t overlook external resources that can accelerate your journey. Many regions offer financial incentives and support programs specifically designed to help smaller businesses adopt advanced manufacturing technologies. Industry consortiums provide access to shared resources and expertise that would be unaffordable individually.

Learning from peers who’ve already traveled this path can provide invaluable shortcuts and practical insights. Industry associations and manufacturing extension programs often facilitate these connections, creating communities where smaller organizations can share experiences and best practices.

Future Trends

The evolution of hi tech lean continues to accelerate, with several exciting developments on the horizon. Machine learning algorithms are becoming increasingly sophisticated at driving autonomous process optimization – not just identifying improvement opportunities but implementing changes with minimal human oversight.

Extended reality technologies (virtual, augmented, and mixed reality) are changing training, maintenance, and operational activities. Imagine a maintenance technician wearing AR glasses that highlight exactly which component needs attention and display step-by-step repair instructions overlaid on the actual equipment.

Blockchain technology promises to extend lean principles across organizational boundaries by enabling end-to-end supply chain visibility and traceability. This transparency will help eliminate waste and improve coordination throughout entire value networks.

The rollout of 5G networks is enabling more sophisticated edge computing applications, bringing analytics and decision-making closer to the point of action. This reduces latency and enables real-time responses to changing conditions.

Perhaps most significant is the emergence of integrated digital ecosystems that connect manufacturers, suppliers, and customers in seamless networks that optimize the entire value chain. These platforms will increasingly blur traditional organizational boundaries, creating new opportunities for collaboration and shared value creation.

As environmental concerns grow more urgent, sustainability metrics are being integrated into hi tech lean systems. Tomorrow’s optimization algorithms will balance traditional performance measures with environmental impact, helping organizations achieve both business and sustainability goals simultaneously.

Organizations that stay attuned to these trends and adapt accordingly will be best positioned to realize the full potential of hi tech lean in the coming years. The journey may be challenging, but the destination offers rewards that few other business initiatives can match.

Frequently Asked Questions about Hi Tech Lean

What skills do employees need in a hi tech lean environment?

Transitioning to a hi tech lean environment doesn’t mean replacing your workforce – it means empowering them with new skills. Think of it as an evolution rather than a revolution in how your team works.

Digital literacy forms the foundation of these new skills. Your team doesn’t need to become programmers, but they should feel comfortable navigating touchscreens, using tablets on the shop floor, and interacting with digital dashboards. Most employees adapt quickly when training is hands-on and relevant to their daily work.

Problem-solving remains at the heart of hi tech lean, just with better tools at everyone’s fingertips. Your team needs to understand the basics of how data tells a story – recognizing when something is trending in the wrong direction or spotting unusual patterns. This data-informed problem-solving creates a powerful combination of human insight and digital precision.

Perhaps most valuable is the ability to work across traditional boundaries. In our work with manufacturing teams, we’ve seen how hi tech lean breaks down silos between production, maintenance, quality, and IT. The most successful employees are those who can collaborate effectively with colleagues from different backgrounds, combining their unique perspectives to solve complex problems.

Above all, a growth mindset makes the biggest difference. Technology continues evolving, and the willingness to learn, adapt, and experiment separates the companies that thrive from those that merely survive in today’s manufacturing environment.

How long before we see ROI from hi tech lean?

One of the most common questions we hear is about the timeline for seeing returns on hi tech lean investments. The good news? You don’t have to wait years to see meaningful results.

Most organizations see their first tangible benefits within 3-6 months of starting a focused pilot project. These early wins might include reduced quality issues, faster changeovers, or improved on-time delivery in a specific production area.

For full-scale implementations, expect a journey of about 12 months before seeing transformative results across your operation. That said, you’ll experience incremental improvements throughout this period – it’s not an all-or-nothing proposition.

The financial returns typically arrive faster than many expect. According to data from KSolutions’ customers, most major process improvement projects deliver ROI in less than one year. This rapid payback helps build momentum and secure support for continued investment.

What accelerates your ROI timeline? Start with your most painful problems – the bottlenecks causing delays, quality issues driving customer complaints, or manual processes consuming excessive labor. Addressing these high-impact areas first creates both financial returns and organizational energy for the next phase of improvements.

Technology choice matters too. Cloud-based solutions typically show faster returns than custom-developed systems, simply because they can be implemented more quickly with less IT overhead. This makes them particularly valuable for companies wanting to test the hi tech lean approach before committing to larger investments.

Can hi tech lean work in small-batch or custom production?

If you produce custom products or small batches, you might wonder if hi tech lean is relevant to your operation. The answer is a resounding yes – in fact, high-mix, low-volume manufacturers often see the most dramatic benefits.

Traditional lean methods sometimes struggled with custom production, but hi tech lean excels in these environments. Digital work instructions can instantly adjust to show operators exactly how to build today’s custom order, eliminating confusion and reducing errors. One medical device manufacturer we worked with reduced training time by 60% by implementing tablet-based instructions with embedded videos for complex assemblies.

Flexible automation has transformed what’s possible in custom production. Collaborative robots (cobots) can be quickly reprogrammed for different products, making automation practical even for short runs. Unlike traditional robots that required safety cages and specialized programming, these user-friendly machines can work alongside your team, handling repetitive tasks while humans focus on the custom aspects that require judgment and dexterity.

Quick-changeover technologies dramatically reduce the time between batches, making smaller runs economically viable. Digital tools guide operators through changeover steps, ensuring nothing is missed and eliminating the trial-and-error adjustments that waste valuable production time.

Perhaps most powerful is the ability to practice “mass customization” – building custom products from standardized components and processes. Hi tech lean helps identify which elements can be standardized (reducing complexity) while efficiently managing the truly custom elements that differentiate your products.

Companies producing everything from custom furniture to specialized electronics have transformed their operations with these approaches, achieving both the personalization their customers demand and the efficiency their business requires.

Conclusion & Next Steps

The journey toward hi tech lean excellence is both challenging and rewarding. Throughout this guide, we’ve seen how blending traditional lean principles with cutting-edge digital technologies creates powerful opportunities that can transform your operations.

Key Takeaways

When implemented properly, hi tech lean becomes a game-changer for organizations willing to accept change. It’s not just a set of tools but a complete rethinking of how we approach manufacturing and service delivery in the digital age.

The numbers speak for themselves – productivity improvements of up to 400% and return on investment typically achieved in less than a year aren’t just marketing claims, they’re documented results from real-world implementations. What makes hi tech lean particularly exciting is that it’s not reserved for giant corporations with endless budgets. Cloud-based solutions and modular approaches have democratized these methodologies, making them accessible to businesses of all sizes.

While the technology component gets much of the attention, successful implementation requires equal focus on people, processes, and technology. The human element remains central to hi tech lean success.

Looking ahead, emerging technologies like AI, extended reality, and 5G-enabled edge computing will continue to shape the evolution of hi tech lean, creating even more powerful opportunities for those prepared to accept them.

Starting Your Hi Tech Lean Journey

If you’re feeling inspired to begin your own hi tech lean change, the most successful implementations follow a thoughtful, measured approach:

Start small, scale fast by focusing initial efforts on specific pain points where you can demonstrate value quickly. These early wins build momentum and support for broader initiatives. Nothing convinces skeptics like tangible results!

Build a strong foundation by ensuring basic lean principles are well-established before adding complex technologies. Digital tools will amplify your existing processes – both the good and the bad – so addressing fundamental issues first is essential.

Develop your people through comprehensive training and thoughtful change management. The most sophisticated technology in the world won’t drive results without skilled, engaged team members who understand both the how and the why behind the changes.

Choose partners wisely by selecting technology providers and implementation partners with proven experience in both lean methodologies and digital technologies. The real magic happens at the intersection of these disciplines.

Measure what matters by establishing clear baseline metrics and tracking progress consistently. Combine operational and financial measures to demonstrate value and guide your improvement efforts.

Continuous Improvement Mindset

Perhaps most importantly, approach hi tech lean with a genuine continuous improvement mindset. This journey never truly ends – new technologies, methodologies, and competitive challenges will continually emerge. The organizations that thrive will be those that build cultures of learning, experimentation, and adaptation.

At BuyWockhardt.com, we understand the importance of continuous improvement and efficiency in all aspects of business operations. While our focus is on providing high-quality pharmaceutical products with exceptional service, we appreciate the value that methodologies like hi tech lean bring to organizations across industries.

The principles of waste reduction, process optimization, and customer focus that underpin hi tech lean align perfectly with our own commitment to operational excellence and customer satisfaction. We strive to incorporate these values into our own operations as we serve customers throughout the United States, Deutschland, Japan, and beyond from our Fresno, California headquarters.

For more information about hi tech lean best practices and how they can transform your organization, visit BuyWockhardt.com or reach out to industry experts who can guide your implementation journey. Remember – the most important step is simply getting started!